Case Study: Custom Protection Solution for Prefabricated Mullions in 6 Star Green Star Building Project

Project Details

- Active Metal for Hutchinson Builders

- 360 Queen Street, Brisbane Queensland

Products Used

Key Outcomes

- Temporary protection solution supported sustainability goals

- Collaboration delivered custom protection solution for prefabricated

components - 14 metre mullions remained damage free throughout foyer construction

Background

360 Queen Street in Brisbane Queensland, is a premium-grade commercial tower located in the heart of Brisbane. The 6 Star Green Star building offers over 45,000 sqm of office space across 33 levels and is designed to be a Climate Active Carbon Neutral Building.

Challenge

As part of the construction, 28 structural steel columns (mullions), each 14 metres high, were fabricated and painted with a complex three-part metallic coating at the factory. To maintain the building’s 6 Star Green Star rating, no painting or touch-ups were allowed on-site after installation. This created a significant challenge in protecting the pre-finished mullions during transportation and throughout the construction process to prevent any damage, as replacing or repairing the columns after installation was not feasible.

Architectural visualisation of 360 Queen Street.

Solution

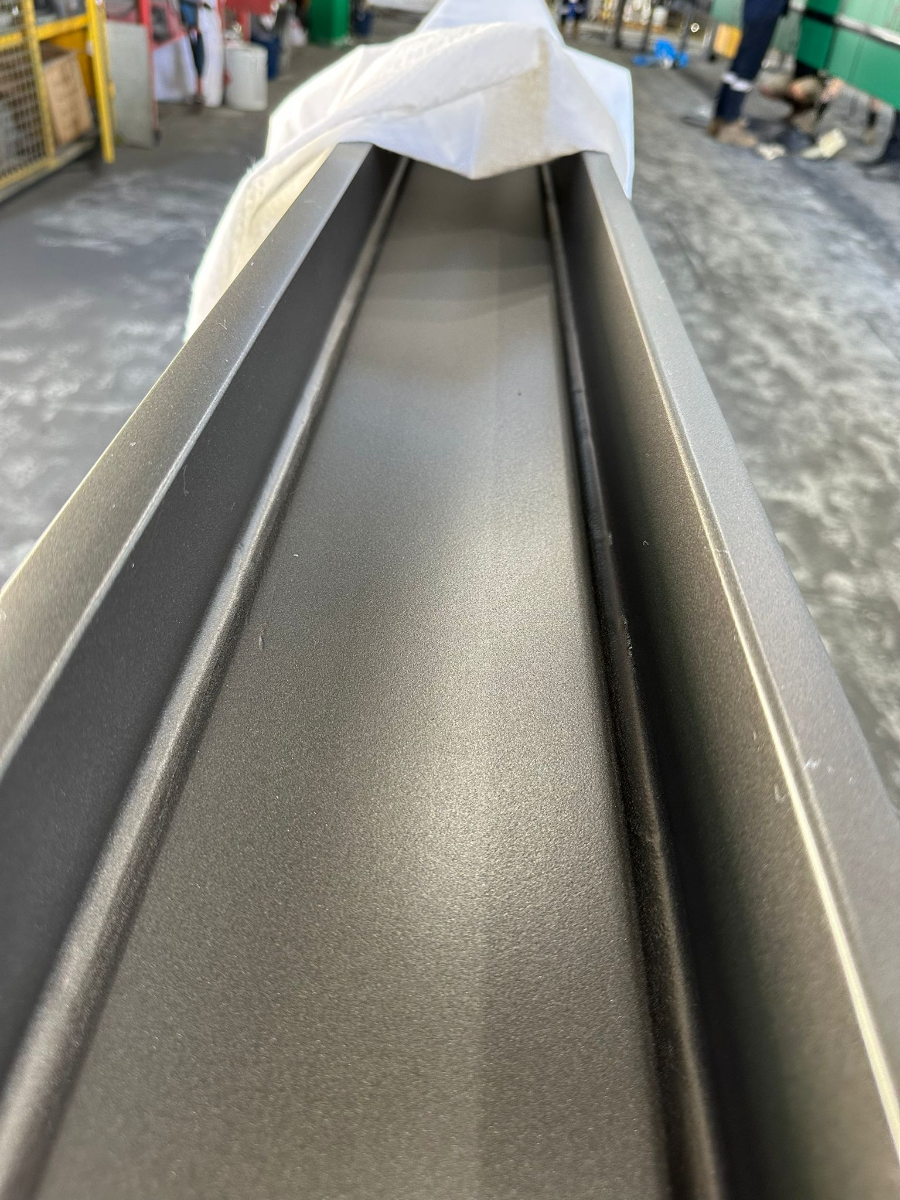

To protect the steel mullions including the finished paintwork, a custom solution was required. By collaborating closely with Active Metal, 14 unique Protecta Board XTRA Custom Profiles were specified to fit the exact dimensions of the mullions using detailed shop drawings.

In all, an astounding 652 Protecta Board XTRA Custom Profiles were produced and applied at the fabrication factory to ensure comprehensive protection of the columns during transit and installation.

Top left and right: 14 metre steel mullions being fabricated and painted at factory.

Bottom left and right: Prefabrication of steel mullions with three-part metallic paint finish.

Final Result

After 10 months on-site, the Protecta Board XTRA Custom Profiles were removed to reveal the soaring mullions in pristine condition, with no damage sustained.

The pre-finished approach not only ensured the integrity of the columns but also contributed to time and cost savings. The installation process was completed without incident, maintaining the building’s 6 Star Green Star rating.

Hutchinson Builders, the main contractor, expressed satisfaction with the solution, noting that the protection withstood everything thrown at it during construction on-site, ensuring that the premium finish remained intact.

Download the Full Case Study

Top left: Variety of Protecta Board XTRA Custom Profiles, specified to protect each unique steel mullion.

Top right, middle right and bottom left: Protecta Board XTRA Custom Profiles secured to steel mullions, ready for transport.

Bottom right: Transporting protected steel mullions to 360 Queen Street site.

Top left: Manoeuvring steel mullions into position for installation in foyer of 360 Queen Street.

The remaining images on this page: Steel mullions safeguarded with Protecta Board XTRA Custom Profiles during foyer construction phase.